Feature Wall Metal Panel Installation at Texas Health Resources, Frisco, TX

Project Details

- Client: General Contractor

- Location: Texas Health Resources, Frisco, TX

- Scope: Design, fabrication, and installation of large aluminum feature wall panels

Project Overview

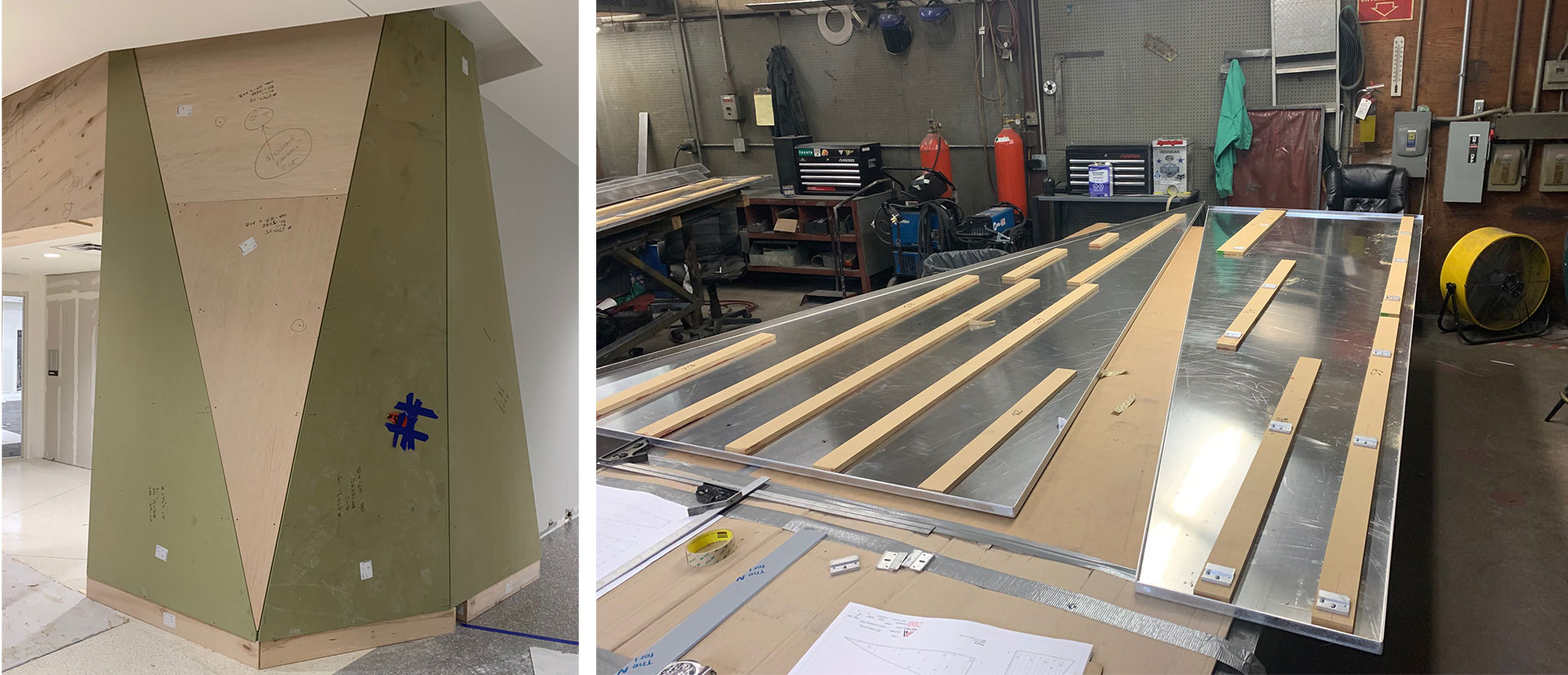

Astro was contacted by the general contractor overseeing the construction at Texas Health Resources in Frisco, TX, regarding a large metal panel feature wall. The project presented a unique challenge: The triangular aluminum panels didn’t fit neatly into the scope of glazing or millwork, requiring a specialized metal fabrication and installation approach. The architect’s vision called for large, triangular panels—some reaching heights of 13 feet and widths of 6 feet—arranged at various angles to create a striking three-dimensional effect. Astro leveraged its precision field measurement, 3D modeling, and expert metal fabrication expertise to bring this ambitious design to life.

Challenges & Solutions

1. Complex Geometry & Precise Fit

- The feature wall had unusual angles and several planes, which made traditional measurement and installation methods difficult.

- Astro performed on-site field measurements and utilized AutoDesk Inventor to develop an accurate 3D model of the wall and panel layout.

- This digital modeling ensured that all panels were manufactured to exact dimensions with ½” reveals between each panel. .

2. Fabricating Large, Seamless Panels

- The triangular aluminum panels, some measuring up to 13 feet by 6 feet, needed to be fabricated from .125” aluminum while preserving structural integrity and clean aesthetics.

- Astro laser-cut and welded the panel corners, ensuring durability while preserving the crisp, geometric design.

3. Secure & Hidden Mounting System

- The installation method needed to support the weight of the panels while concealing hardware to maintain a seamless visual effect.

- Astro attached MDF strips to the back of each panel and mounted Star Hanger 420 S Clips to the MDF.

- A mating Z-bar system was installed on the wall, enabling the panels to be securely hung in place.

4. On-Site Painting & Final Adjustments

- The panels were designed for on-site painting after installation, necessitating precise alignment and spacing to achieve a polished final appearance.

- Astro’s meticulous field dimensioning and precise fabrication ensured the panels fit together seamlessly, enabling the general contractor to complete the painting effortlessly.

Fabrication & Installation Process

- Field Measurement & 3D Modeling

- On-site measurement of the wall’s intricate geometry.

- Modeled the wall in AutoDesk Inventor, ensuring precise panel layout.

- Panel Fabrication

- Laser-cut .125” aluminum panels, welded corners for structural integrity.

- MDF backing with Star Hanger 420 S Clips added for secure installation.

- Mounting System Implementation

- Mating Z-bars are installed on the MDF-clad wall for easy, secure hanging.

- Panels were carefully placed and adjusted to maintain ½” reveals.

- Final Installation & On-Site Finishing

- Once installed, the general contractor painted the panels on-site to complete the final aesthetic.

Results & Impact

- Architectural Excellence: The finished feature wall realized the architect’s vision of an engaging, three-dimensional installation.

- Precision & Seamless Execution: Astro’s careful measurements and 3D modeling ensured a perfect fit despite odd angles and varying planes.

- Durability & Functionality: The strong aluminum panels offer a long-lasting, low-maintenance solution while preserving a high-end aesthetic.

- Efficient Installation & Coordination: Astro’s careful planning simplified the installation process, guaranteeing timely completion and minimal on-site adjustments.

Conclusion

Astro’s expertise in complex metal fabrication, digital modeling, and precision installation was essential to the success of the Texas Health Resources feature wall project. By employing innovative design solutions and expert craftsmanship, we delivered a stunning, architecturally significant installation that satisfied the project’s aesthetic and functional requirements.

Keywords:

Astro Sheet Metal

Sheet metal Dallas

Architectural metal

Custom architectural metal

Custom metal fabrication

Custom sheet metal

Sheet metal Texas

Sheet metal Fort Worth

Sheet metal Grand Prairie

Custom brake metal

Custom decorative metal

Custom ornamental metal

Architectural metal

Decorative metal

Ornamental metal

Shearing

Forming

Laser cutting

Welding

Painting

Field measuring

Autodesk Inventor

CAD Design

Installation

Submittal drawings

Mockup samples

Star Hanger 420 S Clip

1/8″ Aluminum panels

Feature wall

Interior wall panels

Project Overview

Astro was approached by a commercial glazing contractor involved in constructing the Trinity Broadcasting Network’s headquarters in Fort Worth, TX. In addition to providing a glass handrail, the contractor was responsible for cladding the stairs in brushed stainless steel, fabricating and installing a stainless steel rail to cap the glass, and producing matching stainless steel toe kicks for the stair treads.

Given the complexity of the staircase and its structural variations, Astro played a vital role in ensuring that every piece of cladding was accurately fabricated and properly fitted. Our team provided on-site measurements, 3D modeling, laser cutting, and precision forming to achieve a seamless and visually impressive result.

Challenges & Solutions

1. Addressing Step Variations in Field Measurements

- As one of the final trades on-site, we found that each step had slight variations, necessitating careful individual measurements to ensure a precise fit.

- Astro performed thorough on-site field measurements to accurately capture each step’s exact dimensions.

2. Precision Modeling & Fabrication

- Using the collected measurements, Astro created a 3D model of the staircase in AutoDesk Inventor to determine the exact shapes and dimensions needed for each stainless steel panel.

- This digital modeling allowed us to preemptively adjust for inconsistencies, ensuring a smooth installation.

3. Maintaining Grain Direction & Aesthetic Consistency

- The brushed stainless steel panels required a consistent grain direction to attain a polished and unified appearance.

- Each piece was laser-cut and formed with a press brake, ensuring careful attention to grain alignment.

4. Organized Labeling & Installation

- Astro labeled each piece to ensure a smooth and efficient installation process, allowing installers to quickly identify and place the correct panels in their designated locations.

- The parts were delivered to the job site and installed seamlessly, creating a refined and professional finish.

Fabrication & Installation Process

- On-Site Field Measurement

- Careful measurement of each step to account for variations.

- 3D Modeling & Design

- Modeled the staircase in AutoDesk Inventor to define precise shapes and dimensions.

- Precision Fabrication

- Laser-cut stringer cladding pieces for a perfect fit.

- Press-brake formed panels with attention to grain direction.

- Organized Labeling & Preparation

- Each component was labeled and prepped for installation, reducing errors and streamlining the process.

- Installation & Final Results

- Brushed stainless steel cladding, handrail caps, and toe kicks were installed on-site, completing the sophisticated and eye-catching staircase.

Results & Impact

- Seamless Integration: The brushed stainless steel cladding and components fit precisely, creating a sleek and modern aesthetic.

- Durability & Functionality: Stainless steel provides long-term durability, enhancing the staircase’s visual appeal and longevity.

- Precision Execution: Field measurement, 3D modeling, and laser cutting ensured a perfect alignment, overcoming the challenge of step variations.

- High-End Architectural Finish: The completed staircase is a striking architectural feature that enhances the prestige and elegance of the TBN headquarters.

Conclusion

Astro’s expertise in precision metal fabrication, 3D modeling, and installation coordination was vital in delivering a flawless stainless steel-clad staircase at the Trinity Broadcasting Network’s headquarters. This project highlights our attention to detail, problem-solving abilities, and commitment to quality, strengthening Astro’s reputation as a dependable partner for complex architectural metalwork.

Keywords:

Astro Sheet Metal

Sheet metal Dallas

Architectural metal

Custom architectural metal

Custom metal fabrication

Custom sheet metal

Sheet metal Texas

Sheet metal Fort Worth

Sheet metal Grand Prairie

Custom brake metal

Custom decorative metal

Custom ornamental metal

Architectural metal

Decorative metal

Ornamental metal

Stair cladding

Brushed stainless steel

Stringer cladding

Field measuring

installation

Shearing

Forming

Laser cutting

Welding

Refinishing

Autodesk Inventor

CAD Design

Submittal drawings

Mockup samples