Fulfillment Center Cardboard Recycling Solution

Client: Fulfillment Center

Location: Dallas, Texas

Industry: Distribution & Warehousing

Challenge:

This fulfillment center serves as a large, three-level distribution center that generates a significant amount of cardboard waste on each floor. The existing waste handling process involved employees loading the cardboard into buggies, transporting it to the elevators, and then taking it down to the first floor for recycling. This process was time-consuming and inefficient, requiring many elevator trips and manual labor.

The customer was looking for a more efficient way to transport the cardboard from the second and third floors to the recycling area on the first floor, reducing time, labor, and operational disruption.

Solution:

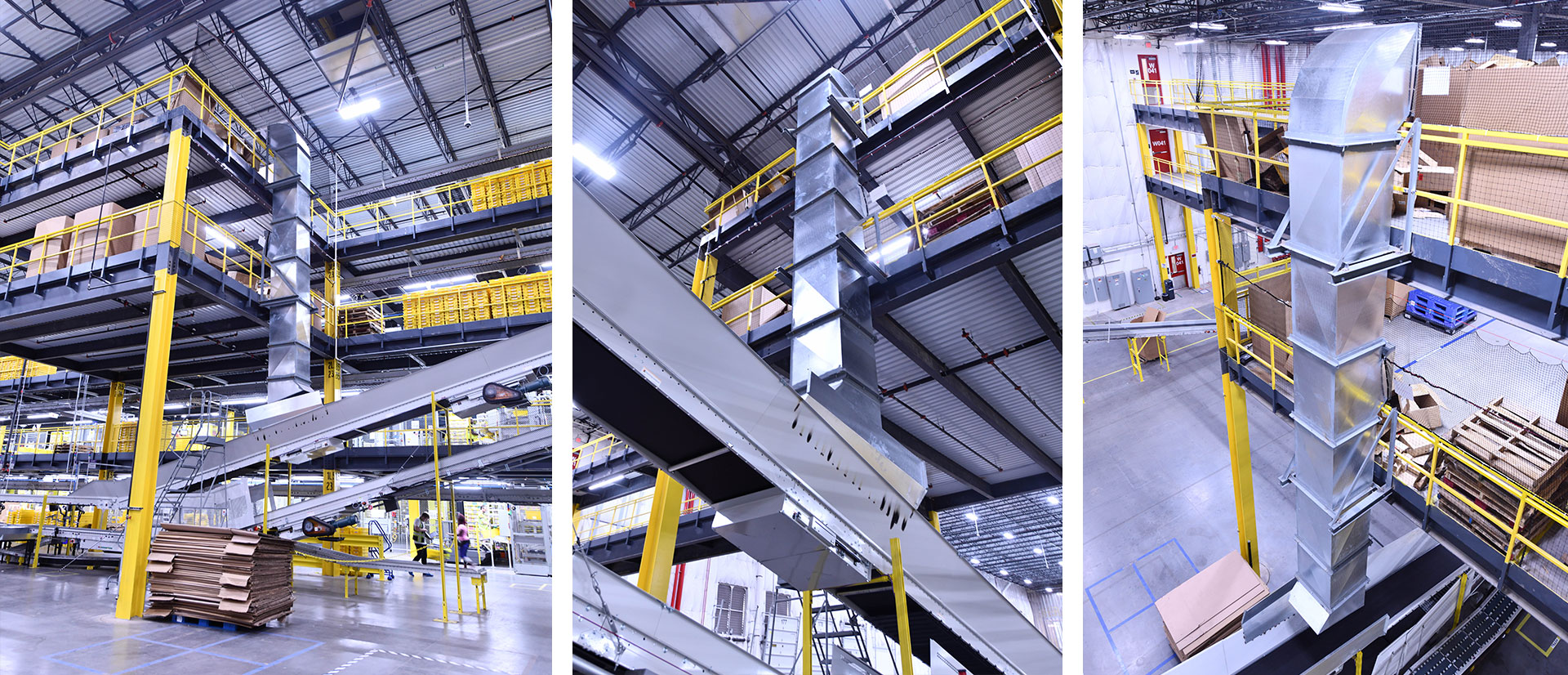

Astro was approached to design and fabricate a solution to streamline this process. Our engineering team developed a plan for a large galvanized steel chute, measuring approximately 48” x 48”, to serve both the second and third floors. The chute would enable employees to deposit cardboard waste directly into it, then transport it to a conveyor system on the first floor. This conveyor would move the cardboard to the recycling area, eliminating the need for elevator trips and manual carting.

Astro’s design featured:

- Dual access points on the second and third floors for easy waste disposal.

- A seamless chute-to-conveyor connection for efficient waste transfer.

- A sturdy galvanized steel construction to withstand the wear and tear of daily use in a high-traffic distribution environment.

- A system that could be easily maintained and integrated into the facility layout.

Process:

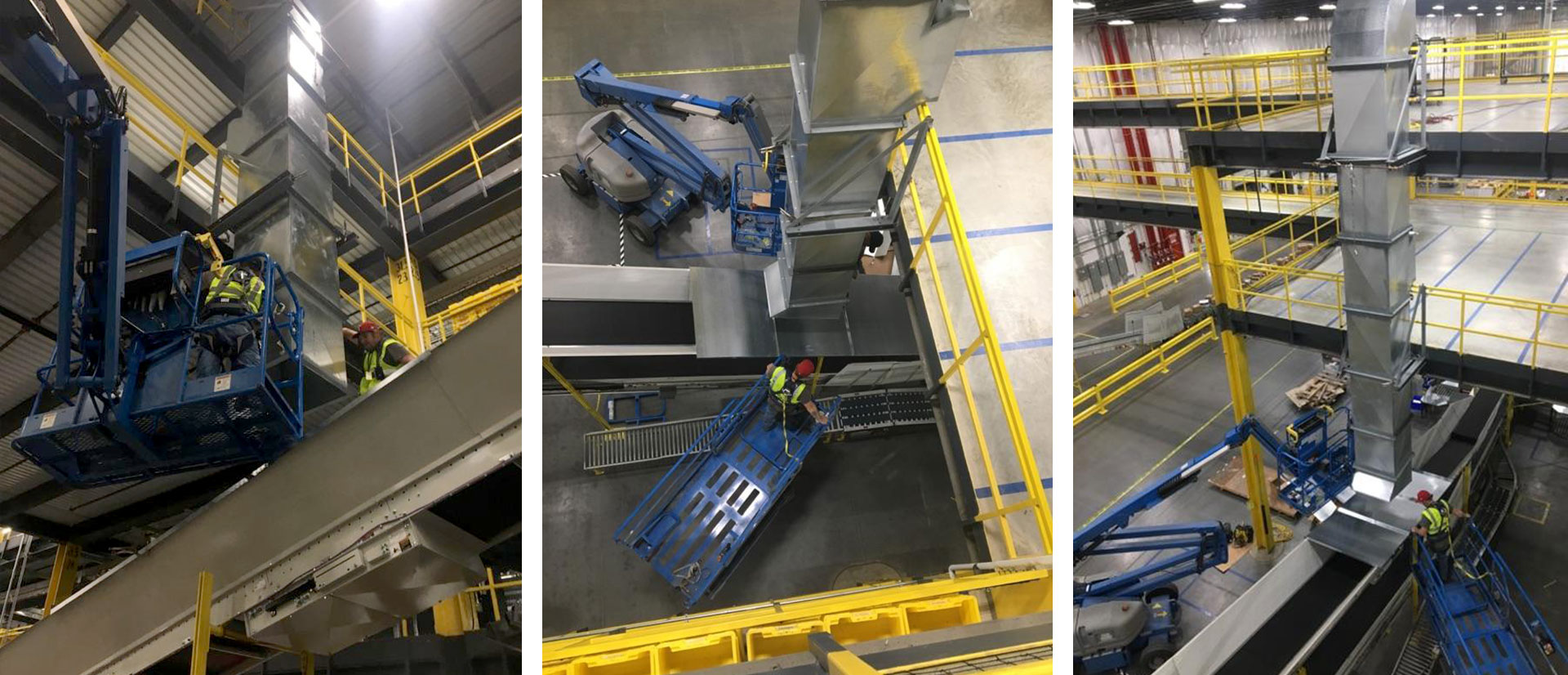

- Site Evaluation & Design: Astro’s team visited the facility to evaluate the layout and grasp the challenges of managing cardboard waste. With this information, our engineers utilized CAD to create a solution that optimizes the cardboard waste management process without interrupting daily operations.

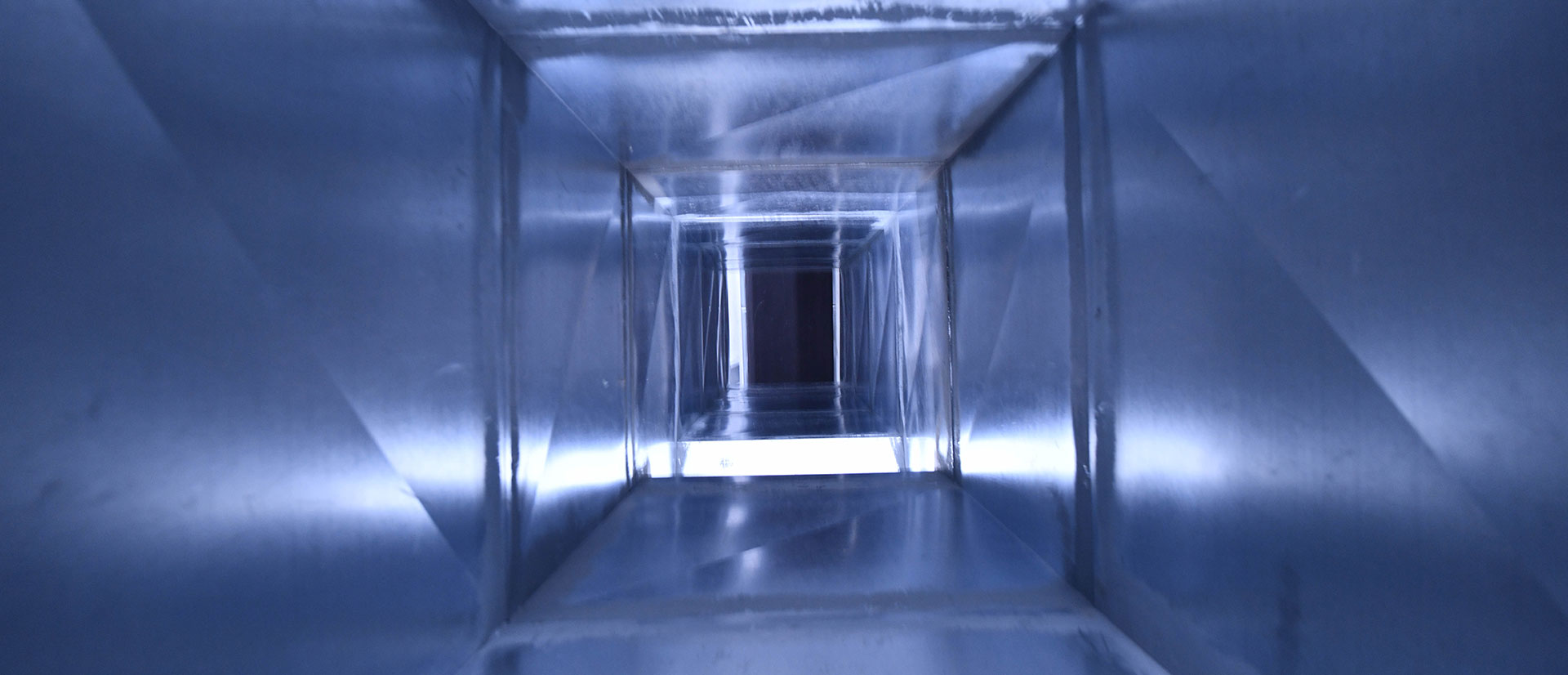

- Chute Fabrication: We started fabricating the galvanized steel chute in our shop after the design approval. The chute was crafted in sections with bolt-together companion flanges for easy assembly on-site. This modular design facilitated a smooth and efficient installation.

- Field Installation: Astro’s team fabricated the necessary hangers to secure the chute. The hangers were field-welded to the facility’s structure, and the chute was carefully assembled on-site. This assembly method minimized the facility’s downtime and ensured the chute was properly secured and aligned.

- Final Integration: The chute was linked to the conveyor system after installation, facilitating a smooth cardboard transfer to the recycling area. The entire system was evaluated for efficiency and functionality.

Results & Impact:

- Time Savings: The chute significantly reduced the number of elevator trips, allowing employees to focus on other tasks and increasing overall productivity.

- Efficiency: The automated process of transporting cardboard waste to the recycling area eliminated the need for manual handling, reducing labor costs and physical strain on employees.

- Sustainability: The streamlined recycling process helped Amazon achieve more efficient waste management, contributing to sustainability goals by ensuring that cardboard waste was recycled promptly and without delay.

Conclusion:

Astro’s innovative galvanized steel chute system provided the fulfillment center with an efficient, time-saving solution for managing the significant volume of cardboard waste produced across three floors. By minimizing manual labor and enhancing operational efficiency, this solution boosted the facility’s productivity and supported a more sustainable recycling process. Astro’s capability to design, fabricate, and install a tailored solution contributed to the project’s success, highlighting our expertise in addressing complex challenges for our clients.

Keywords:

Astro Sheet Metal

Sheet metal Dallas

Custom metal fabrication

Custom sheet metal

Sheet metal Texas

Sheet metal Fort Worth

Sheet metal Grand Prairie

Industrial metal

Shearing

Forming

Laser cutting

Welding

AutoDesk Inventor

CAD Design

Galvanized steel

Industrial chute

Field welding

Installation

Custom metal chute