Custom City Seal for the City of College Station

Client: City of College Station

Location: College Station, Texas

Scope: Fabrication of a custom city seal for the exterior of a government building

Project Overview:

The City of College Station, Texas, needed an official city seal—a long-awaited symbol of civic pride and identity. The seal would serve as a significant visual representation of the city, prominently displayed on the front of the new city hall building. The challenge for the architect was to create a large-scale seal with an embossed look, but with a diameter of approximately 5 feet, traditional embossing methods were not feasible. Astro was called upon to collaborate with the architect to find a way to create the desired effect while meeting the scale and aesthetic requirements.

After discussing various design and fabrication techniques, Astro developed a solution to achieve the embossing look without traditional methods. The final design was to be composed of dozens of individually laser-cut pieces, each meticulously crafted and assembled to create the full-scale city seal.

Design and Collaboration:

1. Conceptualizing the Seal Design

The architect developed the initial concept for the city seal, which features intricate detailing and a raised embossed appearance. The seal’s design was complex, and the challenge was achieving that detailed, dimensional look on such a large scale. While traditional embossing techniques are generally more suited to smaller sizes, the scale of the seal requires a more innovative approach.

Astro worked directly with the architect to translate the design into a feasible fabrication plan. The idea was to maintain the embossed aesthetic while ensuring the end product would be durable, weather-resistant, and visually impactful on a large scale.

2. Developing a Custom Fabrication Technique

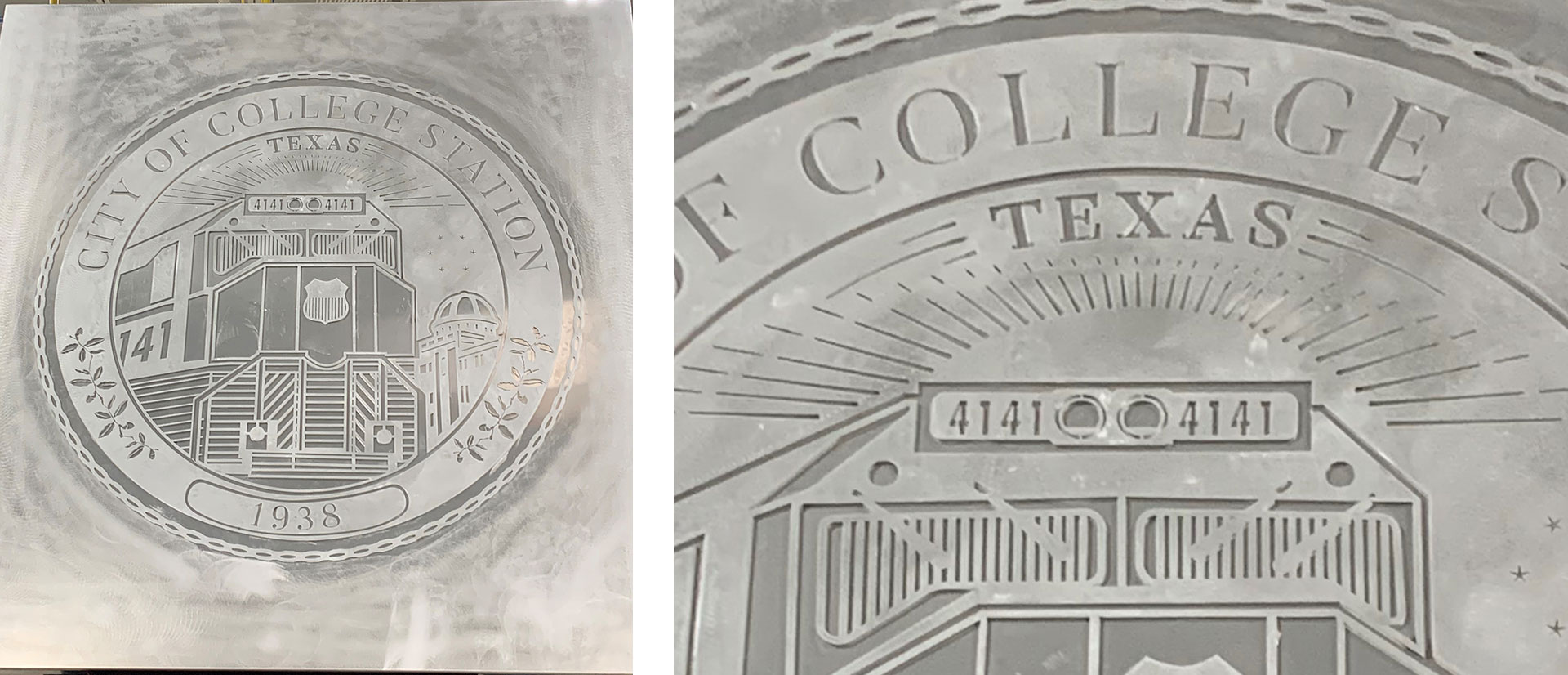

Astro proposed creating individually laser-cut metal pieces raised from a flat surface to achieve the desired raised look. Each piece was cut precisely using our Bystronic fiber laser machine, and the city seal’s outlines and features were shapecut to the design’s specifications.

- Laser-cutting and Stud Welding: The laser-cut pieces were then attached to a large back panel using small studs that were welded to the back of each piece. This allowed each piece to sit slightly above the panel’s surface, giving the appearance of embossing while maintaining structural integrity.

- Mockup Panel: Astro created a small mockup panel before moving to full-scale production to ensure that the raised pieces achieved the correct effect. The mockup was presented to the architect, who approved the design and the method for fabricating the full-size seal. This step ensured the project was on the right track and the desired aesthetic was achievable.

3. Full-Scale Fabrication

Once the mockup was approved, Astro began fabricating the full-size city seal panel. The process involved the following steps:

- Laser-cutting the Pieces: Dozens of individual pieces were laser-cut to fit the whole design of the city seal. Each piece was cut with precision to capture the exacting detail of the design.

- Welding the Studs: Small studs were welded to the back of each laser-cut piece, ensuring that the pieces would be raised slightly above the surface of the large back panel once assembled.

- Assembly: The individual pieces were carefully arranged and welded onto the large back panel. The painstaking assembly process involved fitting each piece into place, ensuring that every element of the seal’s intricate design was accurately represented and that the overall effect was cohesive.

4. Kynar Painting and Finishing

Once the panel was fully assembled, Astro finished the project with a Kynar paint application. Kynar, a high-performance coating known for its durability and resistance to fading, was chosen to match the contoured panels on the front of the building, which Astro also fabricated. The paint ensured the seal’s color matched the building’s aesthetic and provided long-lasting protection against the elements, an essential factor for an exterior feature.

- Precision Painting: The Kynar paint was carefully applied to the large panel, ensuring a smooth, uniform finish that complemented the building’s overall design. The process was executed with great care, as the raised elements of the seal had to remain pristine and free from overspray or defects.

Delivery and Installation:

Astro delivered the nine finished panels to the customer, a glazing contractor after fabrication and finishing were complete. The glazing contractor then installed the panels along with the glass on the exterior of the city hall building.

Final Result: The finished city seal was a stunning visual statement, with the raised elements creating the illusion of an embossed design. The Kynar finish ensured the seal would remain vibrant and protected for years while carefully assembling individual pieces, which gave it a distinct, handcrafted quality.

Challenges and Solutions:

- Large-Scale Embossing: The project’s most significant challenge was replicating the look of traditional embossing on a large scale. Traditional embossing methods were unsuitable for a 5-foot-diameter seal, so Astro worked closely with the architect to develop an innovative solution using laser-cut metal pieces and stud welding.

- Precision and Detail: Achieving the level of detail required for the city seal was a complex task, but Astro’s team excelled at translating the design into laser-cut elements that were both precise and durable. The seal’s intricate design, including fine lines and small components, required extreme accuracy during cutting and assembly.

- Weather Resistance: Since the city seal would be installed on the exterior of the building, ensuring its durability against the elements was a priority. Using Kynar paint provided the necessary protection, ensuring that the seal would look great and withstand the weather conditions in College Station for years to come.

Final Outcome:

Astro’s custom fabrication of the City of College Station’s seal resulted in a visually striking and durable feature for the city’s new hall. The innovative use of laser-cut pieces, stud welding, and Kynar painting achieved the embossed look the architect envisioned while maintaining the integrity and longevity needed for an exterior architectural element. The project was a true collaboration between Astro Sheet Metal, the architect, and the glazing contractor, culminating in a city seal that serves as a proud symbol of College Station’s civic identity.

The successful completion of this project demonstrates Astro Sheet Metal’s ability to take on complex design challenges and execute them with precision, creativity, and attention to detail. The finished seal now stands as a testament to the city’s commitment to its community and the high-quality craftsmanship Astro brings to every project.

In The News

College Station’s new city hall, new city seal | kagstv.com

College Station Dedicates New City Hall and Seal – WTAW | 1620AM & 94.5FM

Keywords:

Astro Sheet Metal

Sheet metal Dallas

Architectural metal

Custom architectural metal

Custom metal fabrication

Custom sheet metal

Sheet metal Texas

Sheet metal Fort Worth

Sheet metal Grand Prairie

Custom brake metal

Custom decorative metal

Custom ornamental metal

Architectural metals Dallas

Decorative metal

Ornamental metal

Shearing

Forming

Laser cutting

Welding

Refinishing

Autodesk Inventor

CAD Design

Submittal drawings

Mockup samples

Custom metal signage

Aluminum panels

College Station City Hall

Kynar painted aluminum

Spandrel panels