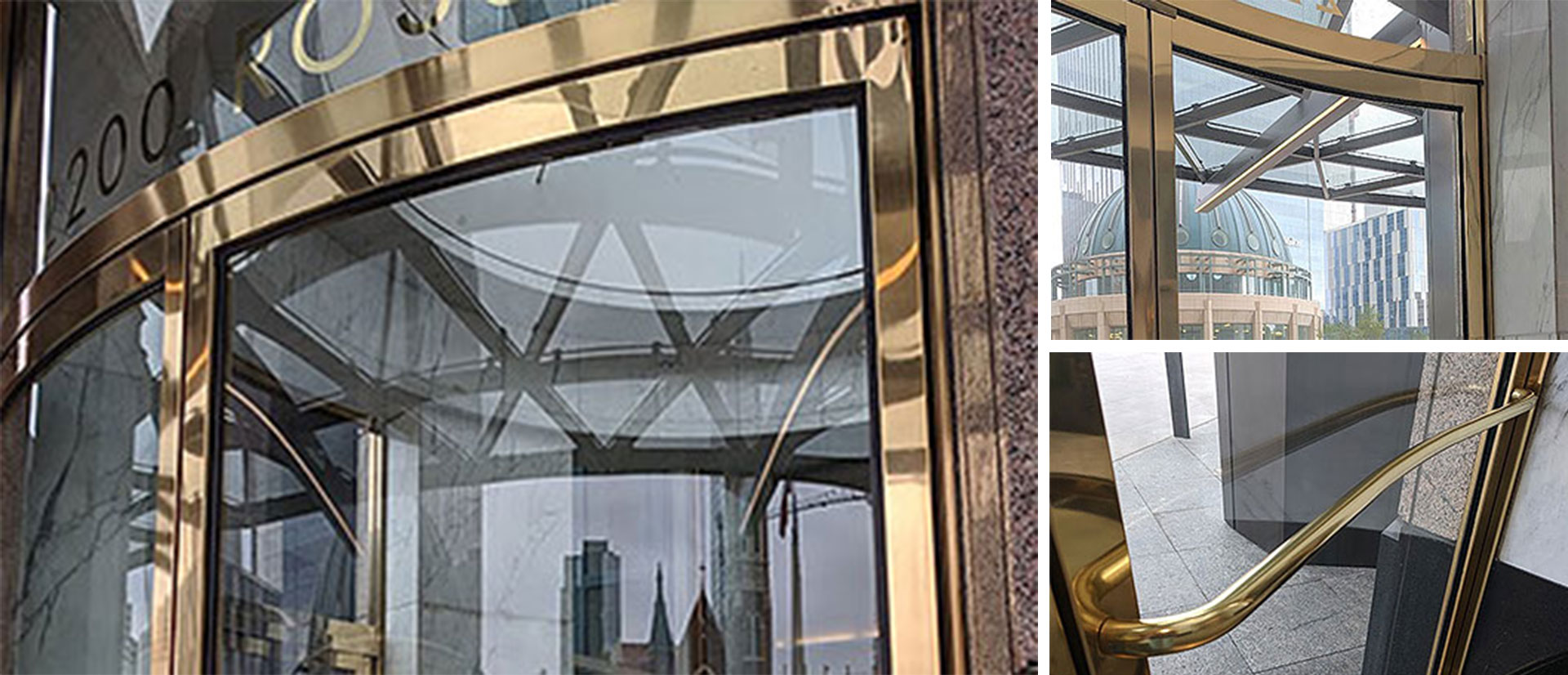

Curved Muntz Brass Cladding for the 2200 Ross Ave Entry Renovation

Project Details

- Client: Glazing Contractor

- Location: 2200 Ross Ave, Dallas, TX

- Scope: Fabrication of curved Muntz brass cladding and custom push bars for entry doors

Project Overview

A glazing contractor approached Astro with a unique architectural challenge. The building owners of 2200 Ross Ave in Dallas, TX, sought to enhance their entryway with elegant Muntz brass cladding, creating a sophisticated, high-end aesthetic. However, this project presented a technical challenge: the entry doors and aluminum extrusions were curved, requiring precision fabrication to ensure a seamless fit. Additionally, the doors required curved brass push bars to complement the design.

Astro utilized its expertise in custom metal forming and finishing to create the curved brass components with precision and durability, ensuring a flawless installation by our client.

Challenges & Solutions

1. Cladding Curved Doors & Aluminum Extrusions

- Traditional flat metal sheets could not conform to the curved surfaces of the entry doors and surrounding extrusions.

- Astro fabricated brake shapes from Muntz brass and had them stretch-formed to the required radii, ensuring an exact fit while maintaining the structural integrity of the brass cladding.

2. Fabricating Custom Curved Brass Push Bars

- The curved doors required matching push bars that followed the same contour for aesthetic and functional consistency.

- Astro rolled and welded the push bars to achieve the proper curvature, ensuring seamless door integration.

3. Achieving a High-End, Durable Finish

- The brass components required a custom brushed finish to enhance their visual appeal while providing long-lasting protection.

- Astro carefully polished the brass to achieve an even finish, followed by applying a clear protective coat to preserve its appearance and durability over time.

Fabrication & Finishing Process

- Precision Fabrication & Forming

- Brake shapes were cut from Muntz brass and formed by stretching to match the required curvatures.

- Push bars were rolled and welded to ensure a continuous, smooth arc.

- Custom Finishing

- The fabricated components were brushed to a high-end finish.

- A clear protective coating was applied to prevent tarnishing and maintain the brass’s elegant appearance.

- Packaging & Delivery

- All fabricated pieces were meticulously packaged and delivered to the client for installation.

- Installation & Final Results

- The glazing contractor successfully installed the curved brass cladding and push bars on-site, achieving a stunning and sophisticated entryway renovation.

Results & Impact

- Seamless Integration: The curved brass components fit perfectly with the entry doors and aluminum extrusions, preserving a high-end architectural aesthetic.

- Durability & Protection: The clear-coated brushed brass finish provides long-lasting resistance to wear and tarnishing, preserving its luxurious appeal.

- Precision Craftsmanship: Astro’s skill in metal forming, welding, and finishing enabled flawless execution, fulfilling the client’s expectations for both form and function.

Conclusion

Astro’s role in the 2200 Ross Ave entry renovation showcases our capability to tackle intricate metal fabrication challenges while achieving architectural excellence. Through precise forming, skilled finishing, and meticulous attention to detail, we delivered a solution that enhanced the elegance and functionality of the building’s entryway.

Keywords:

Astro Sheet Metal

Sheet metal Dallas

Architectural metal

Custom architectural metal

Custom metal fabrication

Custom sheet metal

Sheet metal Texas

Sheet metal Fort Worth

Sheet metal Grand Prairie

Custom brake metal

Custom decorative metal

Custom ornamental metal

Architectural metal

Decorative metal

Ornamental metal

Shearing

Forming

Stretch forming

Muntz brass

Laser cutting

Welding

Brushed Muntz Brass

Clear coat Autodesk Inventor

CAD Design

Brass fabrication