26 Jan Rules of Thumb For Flange Sizes

When you were younger, you may have come up with some imaginative drawings: for example, maybe you drew a dinosaur riding on a rocket! However, just because it could be drawn didn’t mean that it could become reality. The same rule applies to metal design – just because you can draw it doesn’t mean it can be easily achieved! One area where we often see issues is in flanges on metal components being drawn smaller than they can realistically be formed. If you use these rules of thumb when designing your metal parts, you can save yourself the heartache of re-designing late in the game.

1. Minimum Flange Length = 5x The Metal Thickness On The Inside Dimension

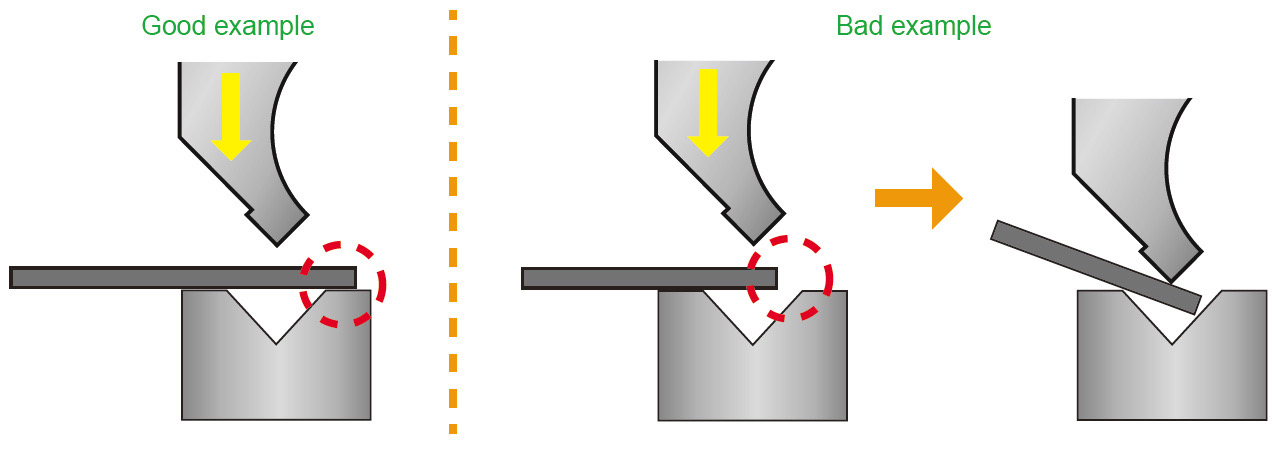

Most press brakes utilize air bending. In order to do so, they require a bottom v-die with an opening of 8x the metal thickness. This means that the area where the punch die comes down and interacts with the metal being bent is at 4x the metal thickness. You need a little bit of material to actually be formed, so a good rule of thumb is that the inside dimension of your flange needs to be at least 5x the metal thickness.

For example: If you are forming .063” Aluminum, then the minimum flange that can be formed is an inside dimension of (5 x .063”), or .313”.

If, instead, you are forming 11 ga stainless steel, then the smallest flange that can be formed is an inside dimension of (5 x .120”), or .600”.

2. However, There Is A Lower Limit As Well

At Astro, the smallest flange we can turn on any material is .25” ID, because these are the smallest dies we have. So, even if the material is 26 ga (.018”) stainless steel, we still can only turn a minimum flange of .25” ID.

3. Not Impossible, But Expensive

We hear customers say, “I have this mass-produced part from XYZ Manufacturing, and it has a .125” flange on it.” Those types of bends are not impossible to achieve – they are just not able to be achieved with conventional tooling. Some companies may have specialty dies made just for a special part that they mass-produce. Others may utilize rollforming equipment to achieve specialty bends. However, the cost of specialty tooling is normally cost-prohibitive unless large volumes of parts are needed. For small custom runs, it is best to adhere to the minimum flange guidelines offered above.

Depending on the material and length of parts, it may also be possible to form flanges longer than needed and then notch or saw them down to the required length. For example, if you have a 5” wide bracket from .125” aluminum that really needs to have a .25” flange on the end, then it may be possible to form this flange at the .625” minimum length and then notch off the excess material to achieve the .25” flange length. This must be evaluated on a case-by-case basis.

Please keep these rules of thumb in mind when designing your metal parts. And if we can ever answer any questions during your design phase, please feel free to reach out to the team at Astro, and we will be glad to advise.