09 Oct Black Anodized vs Black Paint | Architectural Metal Finishes by Astro

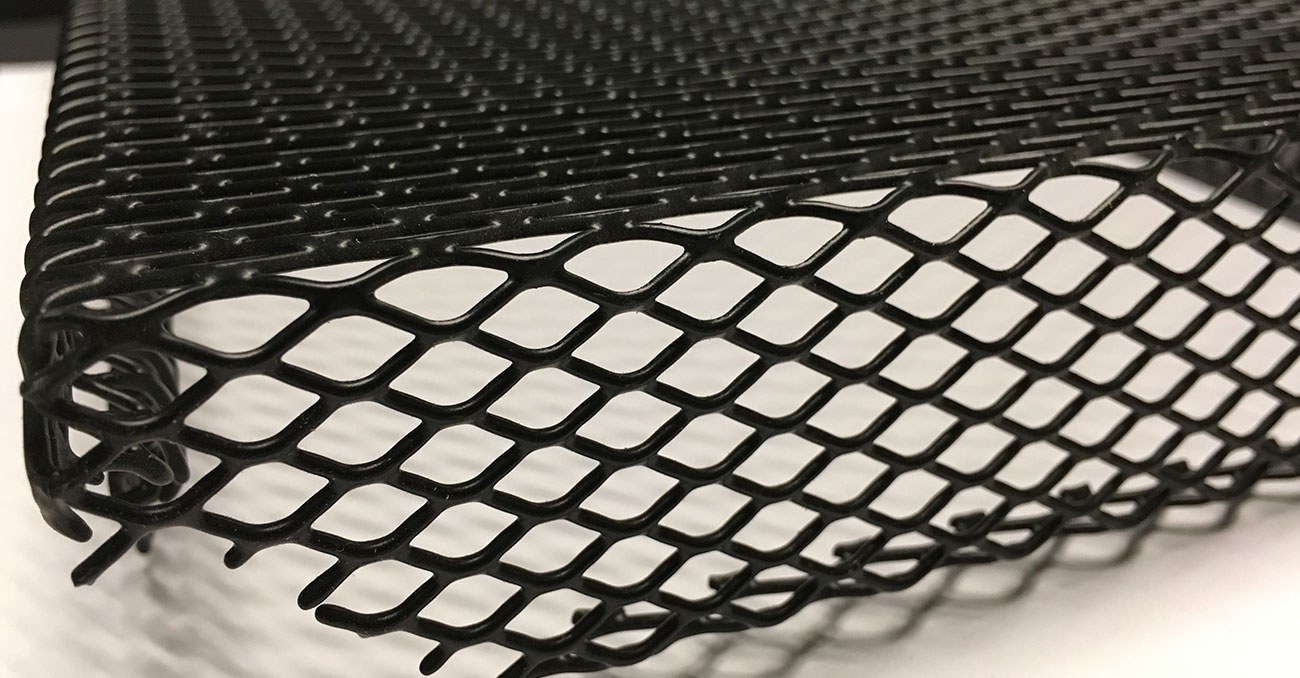

In architectural interiors and exteriors, black metal elements often become focal accents — trim, façades, mullions, decorative screens, and more. But when it comes to achieving a true, durable black finish on metals (especially aluminum), not all methods are equal. At Astro, we help design and construction teams understand the key distinctions between black anodizing and black paint — so the final result lives up to the aesthetic and performance demands of the project.

What Happens Behind the Finish

Black Anodizing

Anodizing is an electrochemical conversion process. The aluminum substrate is treated so that its surface transforms into a semi-porous oxide layer. After that, the pores are dyed (in this case, black) and then sealed. The result is a finish that becomes part of the metal itself — not just applied on top.

Because the color penetrates into the oxide and is sealed, it resists abrasion, chipping, and peeling more effectively than coatings that sit on the surface.

Black Paint / Coating (Powder or Liquid)

Paint is a surface coating applied over the metal. Whether it’s liquid paint or powder coating, the pigment and binder system sit atop the substrate — and it depends on adhesion under variable conditions (substrate prep, curing, weather, cleaning).

While paint allows broad color flexibility, its performance is inherently limited by how well it bonds and how it resists environmental stress.

Durability / Wear Resistance

Very high — integrated into substrate, resists abrasion and peeling

Moderate to high (depending on paint system), but more vulnerable to chips, scratches, and wear over time

Color Options & Matching

More limited palette; black is among the common colors, but precise matching across batches can be challenging

Very wide palette and flexibility; easier to get custom tones or match across different elements

Repairability / Field Touch-Up

Difficult — damage often requires replacement or localized refinishing; matching anodized finish is less forgiving

Easier — paint can often be touched up on site, though color match may shift over long durations

Corrosion Resistance

Excellent, especially when properly sealed

Good, but dependent on coating quality, application, and maintenance

Appearance & Visual Depth

Slight metallic / translucent quality; “blackness” tends to be deep and stable with proper dye and seal

Can be matte, gloss, textured — more expressive visually, but sometimes looks “flat” compared to a well-executed anodized surface

Cost & Process Complexity

Typically more complex—requires electrochemical setup, dyeing, sealing, quality control

Simpler in process, especially for custom colors or complex geometries

When to Specify One Over the Other

- Choose black anodizing when durability and long-term performance matter—especially in high-touch, exterior, or high-traffic interior conditions.

- Choose black paint or powder coating when color flexibility is crucial (brand matches, nonstandard hues) or the geometry is too complex for effective anodizing.

At Astro, we often help architects and designers choose based on context, environment, and intended use — not just aesthetics.