04 Oct Partnering in Precision: Why Design-Assist Is Essential for Custom Architectural Metalwork

When working on high-end architectural and interior projects, the stakes are high: timelines are tight, tolerances are narrow, and every detail matters. At Astro, we believe Design-Assist is not just a service — it’s a philosophy: integrating fabrication expertise early to reduce risk, improve quality, and deliver design intent without compromise.

What Is Design-Assist — and Why It Matters

Design-Assist means bringing your metal fabricator into the conversation during schematic or early design phases — not after everything is decided. The benefits include:

- Identifying challenges in materials, finishes, and connections before they become site problems

- Suggesting design revisions or simplifications to streamline producibility

- Locking in tolerances, interfaces, and detailing across trades (e.g. millwork, stone, glass)

Reviewing concept feasibility from both design and fabrication standpoints

When you bring Astro on board early, you get fewer surprises, fewer RFIs, and smoother installations.

High-Impact Use Cases

Design-Assist adds the most value when your project includes:

- Complex architectural elements combining different materials (metal + wood, glass, stone)

- Feature walls, cladding, or framed systems with tight alignment requirements

- Integrated cabinetry, countertops, or millwork with metal trim

- Exterior metal facades or metal rain screen systems where performance and appearance converge

In such cases, coordination among design, engineering, and fabrication is critical — the earlier, the better.

Best Practices & Process Steps

To gain maximum value from Design-Assist, follow these steps:

- Involve fabrication in Schematic / Concept Design

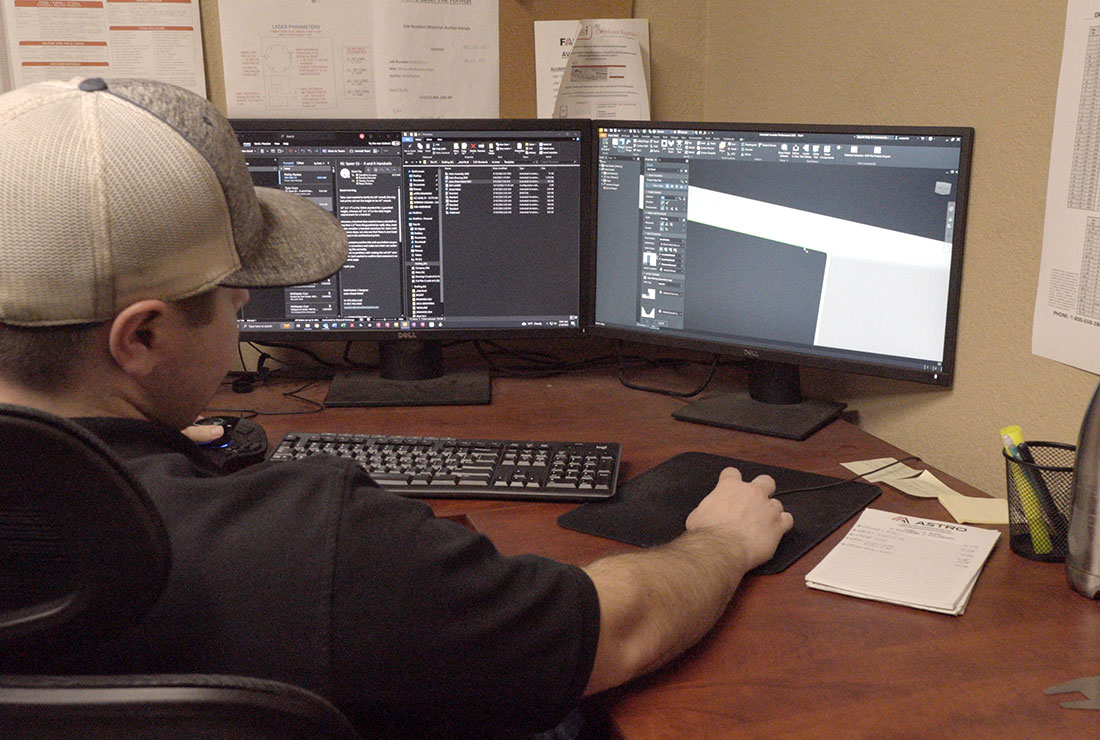

Let Astro review your early designs to identify risks or optimizations. - Share rough models or sketches

Providing even preliminary 3D or section sketches helps us visualize constraints. - Iterate collaboratively on detailing

We’ll help refine how metals meet other materials, reveal lines, support structure, and fasteners. - Make mockups or prototypes

Small-scale models reveal challenges in finish, transitions, or tolerances. - Finalize shop drawings together

Freeze dimensions and sequences before production begins so site issues are minimized. - Maintain communication through construction

We continue collaborating as issues arise in coordination or installation.

Why Astro Brings Unique Value

At Astro, we don’t just build from your drawings — we help shape them. By integrating design insight, fabrication knowledge, and field experience, we provide:

- Proactive design feedback that saves time and cost

- Connection planning and hidden anchoring strategies

- Integration of finishes and transition detailing

- A collaborative approach so the vision survives through construction